The installation of metal ceiling is very different from the installation of general engineering equipment. For common engineering equipment installation, the whole equipment is usually delivered by the factory, put in place after it is ready, and then the pipes and lines are connected to complete the work. Therefore, its main workload is to put the equipment in place and connect the lines. The installation of metal ceiling is to suspend and splice a large number of scattered parts, that is, a single metal plate, according to the drawings until it is completed. Its characteristics are as follows:

1. From scattered to overall forming

The finished area of the ceiling board is generally very small, and the maximum area does not exceed 3 square meters when it leaves the factory. Starting from a single small board, people cannot see the shape of the entire project, so they cannot reflect the function of the ceiling. Only by splicing these scattered ceiling boards together can the design requirements of the project be met. In this process, there are many links, a large workload, and each step must be carefully crafted. This is a veritable secondary manufacturing process.

2. Highlighting the human factor

No matter how the design is improved or the structure is optimized, it is impossible to reduce the workload of on-site construction of the ceiling project, and it is impossible to replace manual labor with mechanization. This has resulted in a situation where the quality of the project must rely on the quality and work attitude of the on-site construction personnel. Therefore, organizing an excellent installation team has become the key to project management. The current actual situation is that the installation team is temporarily assembled and does not have the necessary quality. In this regard, the only way is to send engineers to the site to guide and supervise the installation work.

3. Immutability

Metal ceilings are manufactured by factories, and these products are finalized when they leave the factory. Even if errors are found on site, they cannot be changed. Compared with gypsum board ceilings, they are made on site. If the design is wrong, it will not hinder on-site modification or correction. If the metal plate is wrong, it must be shipped back to the factory for modification, and the round-trip cost and time waste are huge. Therefore, the immutability of metal ceilings puts higher requirements on design and construction, that is, the design and construction preparation should be more careful. When processing special-shaped plates, it is easy to make mistakes in size. One of the errors during the period: the width and length measured on site are inaccurate; the second error: there will be an error of 1mm when the aluminum plate is formed, and the cumulative error of several pieces is a big error, which is difficult to make up. When processing special-shaped panels, technicians must be sent to the site to accurately measure the dimensions, and to make good divisions and layouts.

4. Coordination of on-site construction

The main function of metal ceilings is to cover a variety of pipes and lines. These covered objects must be installed before the ceiling is constructed. At the same time, there are many devices that need to be arranged on the same plane of the ceiling. At this time, the ceiling must be compatible with these devices. These reasons have caused difficulties in the cooperation of various product suppliers and individual construction teams. According to experience, due to various improper cooperation, the ceiling panels have been disassembled and changed many times. This situation is much more serious than expected.

5. Lack of versatility of products

Ceiling products are manufactured according to pre-design. If there are excess products after on-site installation, they cannot be reused or used for other projects. On the contrary, if there is a product missing during on-site installation, the product cannot be called from other projects. This lack of versatility puts higher requirements on the quantity of production, transportation and installation links. Therefore, it is necessary to ensure that the number of products at the time of leaving the factory meets the requirements, and there is no damage during transportation and no damage during installation. If there are returns or missing replenishment due to excess or lack of products, the economic benefits of the entire project will be greatly reduced.

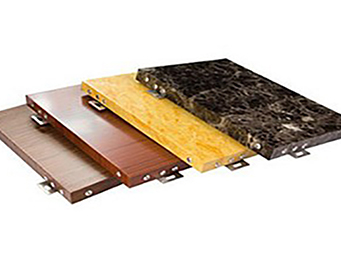

Henan Mingtan is a leading brand in China's aluminum veneer industry, specializing in the production of aluminum veneers, aluminum veneer ceilings, wood grain aluminum veneers, perforated aluminum veneers, fluorocarbon aluminum veneers, carved aluminum veneers, customized aluminum veneers, shaped aluminum veneers, curved aluminum veneers, hyperbolic aluminum veneers, special-shaped aluminum veneers, exterior wall aluminum veneers and other products. It is the designated supplier of many large government projects. Contact number: +86 19555737354 (WhatsApp number).