As a high-end product in architectural decoration, the price of hyperbolic aluminum veneer is relatively high, mainly due to its high cost and complex process. The following is an analysis of the reasons for the high price of hyperbolic aluminum veneer:

High cost factors

The high cost of hyperbolic aluminum veneer is mainly reflected in the following aspects:

Raw material cost: Hyperbolic aluminum veneer usually uses high-quality aluminum alloy materials, which have high strength and corrosion resistance and high price. In addition, in order to meet the design requirements of the hyperbolic surface, the thickness and quality requirements of the material are higher, which further increases the cost.

Production equipment cost: The production of hyperbolic aluminum veneer requires special forming equipment, such as CNC bending machines, molds, etc. These equipment investments are large, and the production cost is naturally high.

Labor cost: The production process of hyperbolic aluminum veneer requires highly skilled technical workers to operate, including mold design, processing, testing and other links. The salary of highly skilled workers is high, and the labor cost increases accordingly.

R&D cost: Due to the difficulty in designing and producing hyperbolic aluminum veneer, enterprises need to invest a lot of R&D resources to ensure the quality and performance of the product, and this part of the cost will also be reflected in the product price.

Complex process

The complex process of hyperbolic aluminum veneer is another major reason for its high price:

Design difficulty: The design of hyperbolic aluminum veneer requires precise surface modeling, which usually requires the use of professional design software for complex modeling and simulation analysis, with a long design cycle and high cost.

Mold manufacturing: The production of hyperbolic aluminum veneer requires special molds. Mold manufacturing is not only complex but also costly. In order to ensure the accuracy and durability of the mold, high-quality materials and advanced processing technology are required.

Forming process: The forming process of hyperbolic aluminum veneer has high requirements, and usually adopts processes such as CNC bending and mold pressing. These processes require high-precision equipment and technology, the production process is complex, and the scrap rate is also high.

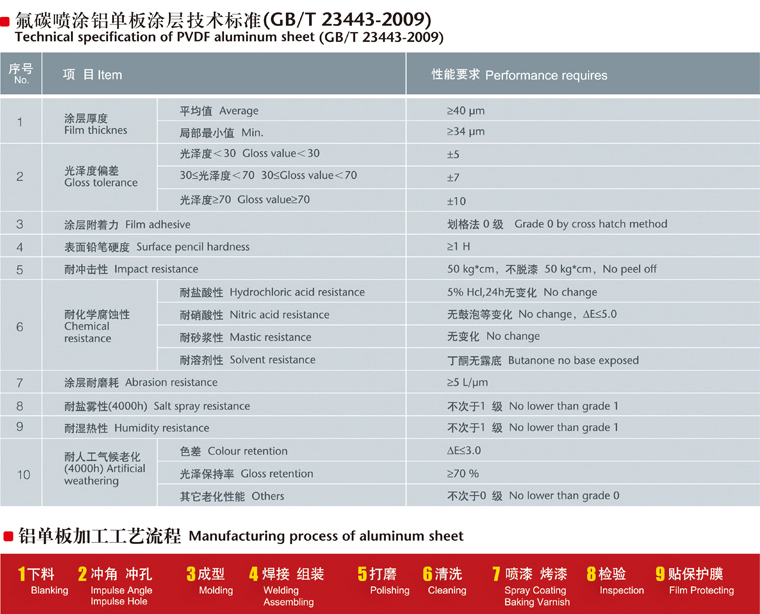

Surface treatment: In order to achieve the ideal decorative effect, hyperbolic aluminum veneer usually requires high-quality surface treatment, such as fluorocarbon spraying, anodizing, etc. These processes not only increase the material cost, but also require high-precision operation and strict quality control.

Installation difficulty: The installation of hyperbolic aluminum veneer is difficult, requiring a professional installation team and precise installation plan. The installation process requires the use of special tools and equipment, and the installation cost is also high.

Customized requirements

Hyperbolic aluminum veneers are usually used in high-end construction projects. These projects have high requirements for the appearance and performance of aluminum veneers and often require customized production:

Personalized design: High-end construction projects have unique design requirements for hyperbolic aluminum veneers, which need to be personalized and customized according to specific projects. The design and production cycle is long and the cost is also high.

Small batch production: Hyperbolic aluminum veneers are usually produced in small batches, with a small production scale, and cannot be reduced through large-scale production. The cost of small batch production is high.

Transportation and installation costs

The transportation and installation costs of hyperbolic aluminum veneers are also high:

Transportation cost: Due to its special curved surface shape and large size, hyperbolic aluminum veneers require special packaging and transportation methods during transportation to prevent deformation and damage, and the transportation cost is high.

Installation cost: The installation of hyperbolic aluminum veneers requires a professional installation team and a precise installation plan. The installation process requires the use of special tools and equipment, and the installation cost is also high.

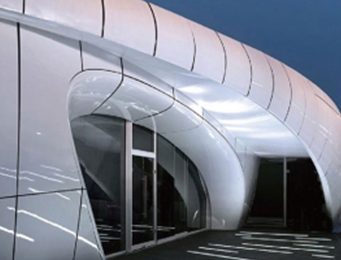

In summary, the high price of hyperbolic aluminum veneers is mainly due to the high costs of raw materials, production equipment, labor, research and development, as well as complex design, molding, surface treatment and installation processes. Customization requirements and high transportation and installation costs have further pushed up the price of hyperbolic aluminum veneers. Despite the high price, the unique decorative effect and excellent performance of hyperbolic aluminum veneers in high-end construction projects make them have high application value.