How to choose and buy exterior aluminum veneers?

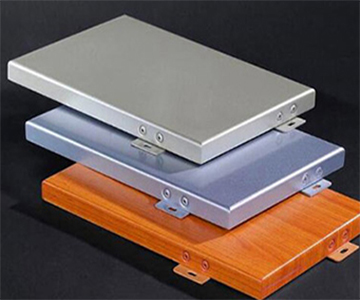

1. Surface treatment of aluminum veneers

Different surface treatment processes of aluminum veneers are directly related to the service life of aluminum veneers. The ranking of aluminum veneer surface treatment processes is as follows: fluorocarbon paint three coats → fluorocarbon paint two coats → fluorocarbon powder spraying → wood grain thermal transfer imitation stone spraying → ordinary polyester powder spraying. The higher the ranking, the better the quality, and of course the more expensive the price. The editor recommends the use of fluorocarbon paint spraying or fluorocarbon powder spraying for the surface process of exterior aluminum veneers for architectural decoration. It has strong weather resistance and corrosion resistance, and can be used for 15-20 years without discoloration or fading. For indoor aluminum veneers, you can choose a cost-effective surface treatment process according to the actual situation.

2. Check whether the manufacturer has cut corners

Carefully check how the surface treatment process of aluminum veneers is done. Now many aluminum veneer manufacturers, in order to attract customers, do not hesitate to quote below the cost price, cut corners, and pass on inferior products. They use non-standard aluminum plate thickness. In order to achieve the product thickness required by customers, they spray thick primers. This practice prevents the primer from being deeply cured on the surface of the aluminum plate, and it is easy to fade and discolor over time. When we see aluminum veneer quotations that are much lower than the general price on the market, we must be cautious. After all, cheap goods are not good. If you keep lowering the price, the aluminum veneer manufacturer will find ways to lower the cost to make a profit, and the customer will be hurt in the end.

3. Correctly choose aluminum veneer manufacturers for cooperation

For large-scale aluminum veneer projects, the editor recommends that you must confirm whether the aluminum veneer manufacturer's factory is large, whether the machine is advanced, and whether the production process meets the requirements of the drawings. Do you know? The quality of the production process directly affects the service life of aluminum veneer products, which is also the most easily overlooked by customers.

4. Check the raw material material of aluminum veneer

According to the national standard for aluminum veneers, decorative aluminum plates are distinguished by grade. Generally, the quality of the curtain wall aluminum veneer material can be judged from the knocking sound. The sound of good aluminum alloy plates is crisp and loud. When purchasing aluminum veneers, you can knock on the aluminum veneer with your hand to try the sound. If there is no big problem with the sound, there must be no problem with the plate. Common materials for aluminum veneers used for architectural decoration are 1100, 3003, 5005, etc. Of course, the higher the aluminum content, the better. If the aluminum content is too high, the hardness of the aluminum plate will not be enough. Therefore, the material of curtain wall aluminum veneer is mostly high-quality alloy aluminum plate, adding metal elements such as manganese, magnesium, and silicon to enhance the hardness of the aluminum plate.

For questions about aluminum veneer price calculation, production process, quality identification, installation and construction process, etc., you can contact and consult us at any time.