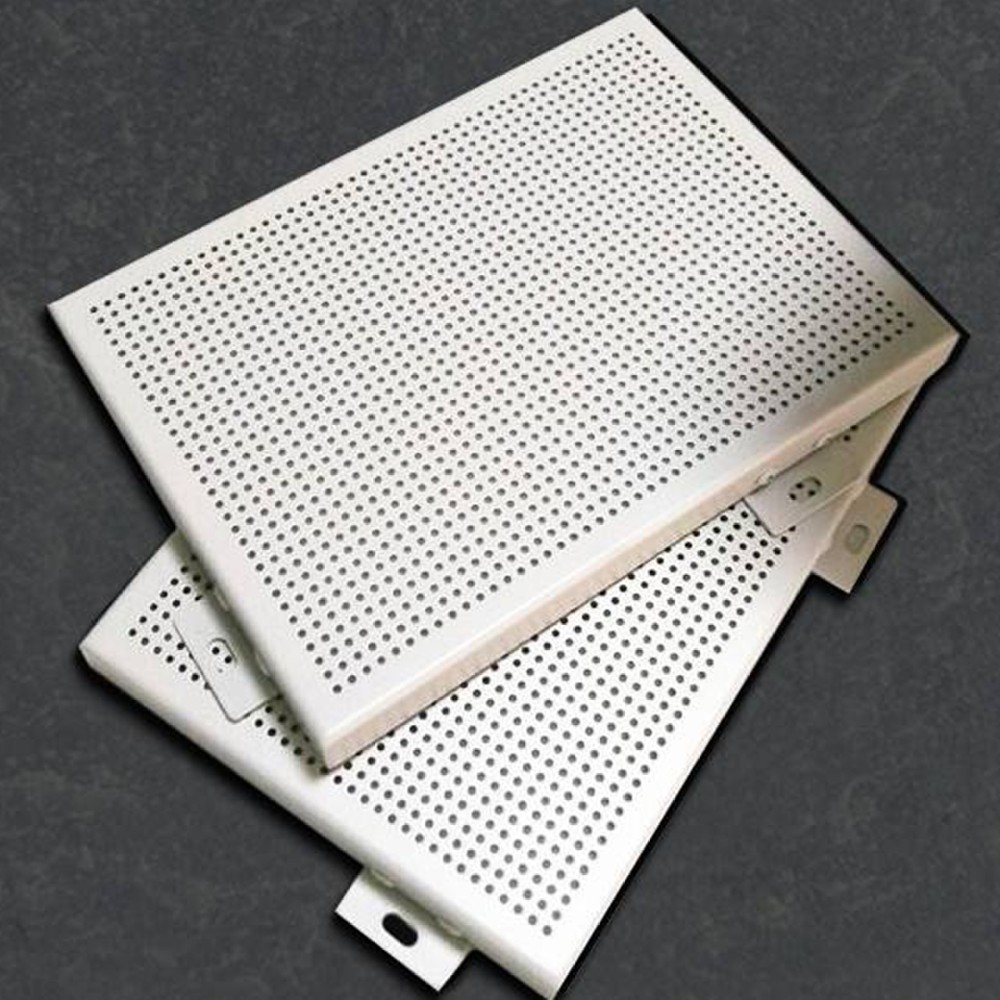

External wall decoration perforated veneer

- Place of Origin:Henan,China

- Brand Name:Hongji Curtain wall

- Certification: CE

- Conventional thickness: 1.5mm、2.0mm、3.0mm、4.0mm、5.0mm、10.0mm

- Short Description: The punching aluminum veneer processing is to cut the original plate from the aluminum coil through the flattening line, and then process it into products of various shapes to meet the different needs of users through a series of processes such as corner cutting, grooving, carving, punching, bending

We're here to help:

Easy ways to get the answers you need.Product Detail

The punching aluminum veneer processing is to cut the original plate from the aluminum coil through the flattening line, and then process it into products of various shapes to meet the different needs of users through a series of processes such as corner cutting, grooving, carving, punching, bending, welding, grinding, drilling, and drawing. After the aluminum plate is processed and formed, it will go through pre-treatment processes such as pickling, water washing, passivation, and then sprayed. Spraying is divided into fluorocarbon spraying and powder spraying.

Fluorocarbon spraying is generally used for the surface treatment of aluminum plates for building exterior decoration. The spraying colors are varied, colorful, and have a long shelf life. It can also spray imitation wood grain or stone color according to user needs. Aluminum veneer processing equipment is easy to serialize, complete, and convenient to establish a production line, which can meet the rapid processing of large quantities of products and process single products with complex shapes.

Aluminum veneer is made of high-quality high-strength aluminum alloy plate. Its regular thickness is 2.0, 2.5.3.0, model is 3003, state is H24, regular material size is 1300mm*2400mm, its structure is mainly composed of panel, reinforcing ribs and angle codes. The angle codes can be directly bent and stamped by the panel, or they can be riveted on the folded edge of the panel. The reinforcing ribs and the thick electric welding screws are connected to make it a solid whole.

Related Products

get in touch

If you have any questions, please fill in the following information and we will respond to you in time.